PCB Holder: Unterschied zwischen den Versionen

Aus Open Source Ecology (OSE) Germany - Entwicklungsplattform

(Änderung 102974 von Djaeger (Diskussion) rückgängig gemacht.) (Markierung: Rückgängigmachung) |

|||

| (38 dazwischenliegende Versionen von 5 Benutzern werden nicht angezeigt) | |||

| Zeile 12: | Zeile 12: | ||

|desc=PCB Holder used for brazing Search Printed circuit boards | |desc=PCB Holder used for brazing Search Printed circuit boards | ||

|TechDoc={{ProjektComponent | |TechDoc={{ProjektComponent | ||

| + | |cmptitle=Test | ||

| + | |cmpimg=<html> | ||

| + | <input type="checkbox"> Item A.<br> | ||

| + | <input type="checkbox"> Item B.<br> | ||

| + | <input type="checkbox"> Item C.<br> | ||

| + | </html> | ||

| + | }}{{ProjektComponent | ||

|cmptitle=PCB Holder technical drawings | |cmptitle=PCB Holder technical drawings | ||

|cmpfile1=01.00 PCB HOLDER.pdf | |cmpfile1=01.00 PCB HOLDER.pdf | ||

|cmpfile2=01.01 Arm.pdf | |cmpfile2=01.01 Arm.pdf | ||

|cmpfile3=01.02 Bracket.pdf | |cmpfile3=01.02 Bracket.pdf | ||

| + | |cmpfile4=01.00 PCB HOLDER new.pdf | ||

| + | }}{{ProjektComponent | ||

| + | |cmptitle=STL_Files | ||

| + | |cmpimg=STL_Files for 3D Printer | ||

| + | |cmpfile1=bracket.stl | ||

| + | |cmpfile2=arm.stl | ||

}} | }} | ||

|Materials={{ProjektMaterials | |Materials={{ProjektMaterials | ||

| Zeile 22: | Zeile 35: | ||

|matdesc=arm | |matdesc=arm | ||

|matquantity=2 | |matquantity=2 | ||

| + | |status_rev_1=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2 | |matpartnumber=2 | ||

| Zeile 27: | Zeile 41: | ||

|matdesc=bracket | |matdesc=bracket | ||

|matquantity=2 | |matquantity=2 | ||

| + | |status_rev_1=in process | ||

| + | |status_rev_2=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3 | |matpartnumber=3 | ||

|matdesc=track | |matdesc=track | ||

|matquantity=1 | |matquantity=1 | ||

| + | |status_rev_1=rejected | ||

| + | |status_rev_2=rejected | ||

| + | |status_rev_3=approved | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=4 | |matpartnumber=4 | ||

| Zeile 37: | Zeile 56: | ||

|matquantity=1 | |matquantity=1 | ||

|status_rev_1=approved | |status_rev_1=approved | ||

| + | |status_rev_2=approved | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=5 | |matpartnumber=5 | ||

| Zeile 42: | Zeile 62: | ||

|matspec=ISO 10511 - M8 | |matspec=ISO 10511 - M8 | ||

|matquantity=4 | |matquantity=4 | ||

| + | |status_rev_1=in process | ||

| + | |status_rev_2=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=6 | |matpartnumber=6 | ||

| Zeile 47: | Zeile 69: | ||

|matspec=DIN 125-1 - B 8,4 | |matspec=DIN 125-1 - B 8,4 | ||

|matquantity=5 | |matquantity=5 | ||

| + | |status_rev_1=approved | ||

| + | |status_rev_2=approved | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=7 | |matpartnumber=7 | ||

| − | |matdesc=hexagon | + | |matdesc=hexagon nut |

|matspec=ISO 4032 - M5 , Typ 1 - Produktklasse A und B | |matspec=ISO 4032 - M5 , Typ 1 - Produktklasse A und B | ||

|matquantity=3 | |matquantity=3 | ||

| + | |status_rev_2=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=8 | |matpartnumber=8 | ||

| Zeile 57: | Zeile 82: | ||

|matspec=ISO 4017 - M5 x 20 | |matspec=ISO 4017 - M5 x 20 | ||

|matquantity=3 | |matquantity=3 | ||

| + | |status_rev_1=approved | ||

| + | |status_rev_2=approved | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=9 | |matpartnumber=9 | ||

| Zeile 62: | Zeile 89: | ||

|matspec=ISO 4014 - M8 x 60 | |matspec=ISO 4014 - M8 x 60 | ||

|matquantity=1 | |matquantity=1 | ||

| + | |status_rev_1=approved | ||

| + | |status_rev_2=approved | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=10 | |matpartnumber=10 | ||

| Zeile 67: | Zeile 96: | ||

|matspec=VD_090W_02_1 STEP AP214 | |matspec=VD_090W_02_1 STEP AP214 | ||

|matquantity=1 | |matquantity=1 | ||

| + | |status_rev_1=rejected | ||

| + | |status_rev_2=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=11 | |matpartnumber=11 | ||

| − | |matdesc=hexagon | + | |matdesc=hexagon nut |

|matspec=ISO 4017 - M5 x 10 | |matspec=ISO 4017 - M5 x 10 | ||

|matquantity=1 | |matquantity=1 | ||

| + | |status_rev_1=in process | ||

| + | |status_rev_2=in process | ||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=12 | |matpartnumber=12 | ||

|matdesc=entire project | |matdesc=entire project | ||

| + | |status_rev_1=in process | ||

| + | |status_rev_2=open | ||

}} | }} | ||

| − | | | + | |certificate_requested=Nein |

| − | | | + | |reviewer1=Lukas |

| − | | | + | |reviewer2=Micha |

}} | }} | ||

Aktuelle Version vom 29. Mai 2020, 09:43 Uhr

|

|

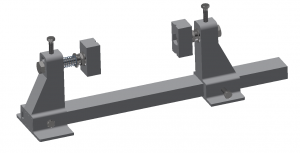

PCB Holder Basic Data Category: Computer, electronics Keywords: PCB Holder

no no no

Other

Design files are in original format: No Free redistribution is allowed licence: No

|

Inhaltsverzeichnis

Description

PCB Holder used for brazing Search Printed circuit boards

Technical documentation

Test | |

| <html>

<input type="checkbox"> Item A. | |

PCB Holder technical drawings | |

Files: | |

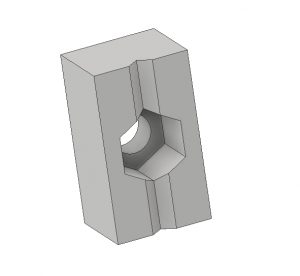

STL_Files | |

| STL_Files for 3D Printer | |

Files: | |

+ General Reviews

Parts list

| Part number | Pos No. | Code | Part Type | Part Name | Specifications | Quantity | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 01.01 | arm | 2 |

REV1: |

|||||

| 2 | 01.02 | bracket | 2 |

REV1: |

|||||

| 3 | track | 1 |

REV1: |

||||||

| 4 | hexagon bolt | ISO 4014 - M8 x 40 | 1 |

REV1: Approved |

|||||

| 5 | hexagon bolt | ISO 10511 - M8 | 4 |

REV1: |

|||||

| 6 | flat washer | DIN 125-1 - B 8,4 | 5 |

REV1: Approved |

|||||

| 7 | hexagon nut | ISO 4032 - M5 , Typ 1 - Produktklasse A und B | 3 |

REV2: |

|||||

| 8 | hexagon bolt | ISO 4017 - M5 x 20 | 3 |

REV1: Approved |

|||||

| 9 | hexagon bolt | ISO 4014 - M8 x 60 | 1 |

REV1: Approved |

|||||

| 10 | compression spring | VD_090W_02_1 STEP AP214 | 1 |

REV1: |

|||||

| 11 | hexagon nut | ISO 4017 - M5 x 10 | 1 |

REV1: |

|||||

| 12 | entire project |

REV1: |

|||||||