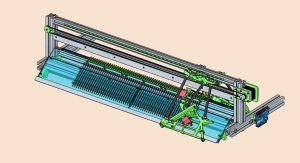

| − | |desc=<div><h3>open source digital knitting</h3><br/><div><div><div><p>Dear OpenKnit followers,</p><p>It’s been a while since my last post. But today, I’m very excited to talk to you about what I’ve been working on during the last months.</p><p>When I started the OpenKnit project, more than 3 years ago, I never expected that it would gather so much interest. Although it begun as a final year project at university, I kept working on it as a hobby. After a long period developing the project in my studio in Barcelona by myself, numerous workshops and exhibitions, and lots and lots of emails and great feedback from all of you (thank you so much), I realized that my vision could be more than that, it could become a reality. What was the next step to bring the OpenKnit project into the future?</p><p>Building a team of amazing people, I moved to Shenzhen, China, as part of , the first and largest hardware accelerator in the world. There I’ve spent the last 4 months reimagining knitting machines.</p><br/><br/><p>Being in China during these months has been an amazing experience. We have met great professionals from all over the world, learnt from very close how things work in a factory and we have been able to develop a completely new machine, from scratch.</p><br/><p>Kniterate, is the name of my new company. We are a young skilled team of 5 people and we are developing the new age of knitting machines, that will change forever how we engage with clothing. A machine that can automate the entire process of creating a garment, rightat your desktop.</p><div><p>Provisional industrial design</p></div><p>But at Kniterate, we want to go further and we want to let anybody easily design, print and wear their unique clothes locally. We are developing and entire ecosystem to foster your creativity. As a part of this ecosystem, we are currently developing an online platform that will soon allow you to design and share your wardrobe online. Start testing our </p><div><p>Sample produced with an early prototype</p></div><p>Join my new adventure and to get updates on our product launch</p><p>Thanks a million.</p><p>All the best,</p><p>Gerard Rubio</p><p>PS: Kniterate is a commercial branch of OpenKnit. It doesn’t belong to this blog. If anyone is interested in taking up the torch of the OpenKnit blog, please let me know. It would be great if more collaborators joined the project and we all kept it moving forward.</p></div><br/><div><p>In October the first OpenKnit workshop was held in Eindhoven, invited by the and the , who had the great idea to take pictures of every step during the assembly process to create a manual and make it easier to the participants, it definitely made us more efficient. The assembly manual will be published very very soon :)</p><p>During November I’ve been doing a residency in makerspace in Milan where I’ve got some great feedback on how to improve the documentation and I’ve spent most of the time working on that. What’s new:</p><p>I designed a shield in Fritzing, you can etch it or print it, or just build it yourself with a stripboard or similar. I produced the first version called LOOP V0.1 with Fritzing (Berlin) and the quality is great.</p><br/><p>I did a couple of little mistakes that are solved in the new V0.2 uploaded, now everything should be ok BUT I haven’t tested this new version so double check that everything is ok if you want to produce it. (note: I have no stock and I’m not selling the shield sorry).</p><p>I also added some STLs that were missing (yarn_carrier, tensor_xxx, cable_grommet) and a few improvements in some parts (sled, sled_arms, top_plate, top_plate_bearings). Added some little components related to the new STLs in the bill of materials.</p><p>I’m currently using for the slider part a 2mm thick piece of polyacetal (POM), sometimes known as Delrin, because it has a lower coefficient of friction than PLA or ABS so the needles can slide up easily, I haven’t tested it with PLA or ABS but it could also work with the help of some grease.</p><br/><p>Another part that is not printed is the eye that feeds the thread to the needles, I thought along with Cees Jan that would be a good idea to have an interchangeable part for changing the thread. I found the plastic part in a cheap costume jewelry shop (note: the cross shape is very suitable for being attached so there is no other meaning/utility for it than placing the thread in the right place).</p><br/><p>After testing it a lot I don’t really find any advantages of being detachable so it could also be printed together with the yarn_carrier part.</p><br/><p>Best regards,</p><p>Gerard and</p></div><br/><br/><div><p>It has been a while since my last post, other activities have kept me very busy after the release of the project. However the visit from Cees Jan Stam, an industrial design master student from the TUDelft, put me back on track. For 3 weeks during the beginning of July we developed a portable version of the OpenKnit. This was done to facilitate the field research part of Cees Jan’s master thesis. This project which focusses on the impact of digital design & fabrication in society. And in order to see how people respond to seeing it out in the world the new machine was developed to be transportable and endure use outside.</p><br/><p>This mend some redesigns were needed, the first generation would not handle all the moving around. We scaled down the machine, this would allow most people to carry it around weighing in at 5kg without the power supply. In order to make it sturdier most of the 3d printed joints were replaced with clean profile on profile connections using a threaded profile and bolt instead. The results are quite impressive, the machine when attached to the table will not move or shake even when in use.</p><p>We did not just make it smaller, while working on the redesign for the smaller machine the rest of the machine was also reevaluated. Some of the issues that were troubling the large machine were severe vibrations and a the encoder placement did not allow for the right accuracy. To combat these issues a new brace was added between the top and bottom of the carriage. We also repositioned the encoder to the top of the carriage in combination with a rack and pinion system, this increased the resolution with 300%. Some minor alterations were also made to the angles of the needle pickup within the bottom of the carriage. While also redesigning the yarn carrier in order to make sure the yarn drop off was perfectly centered in relation to the needle beds. All of these improvements have created a more reliable machine, off course more improvements will be added down the line but it is a good step in the right direction.</p><br/><p>This 4.70m scarf was knitted during 3 hours 25 minutes nonstop, with 3 or 4 minor errors.</p><p>I decided to name the first OpenKnit machines after the famous, and usually lost, character Wally (Waldo in the United States and Canada) because of his unforgettable striped garments. This is exactly what these versions of the machines are meant for, for creating sweaters, beanies, scarfs, socks, etc. that allow you the possibility to change colours by replacing the thread (cut and knot) while working. The number 120 responds to the number of needles the machine is using, so the first machine is called Wally340.</p><br/><p>I haven’t had time to update the documentation of the first machine with the improvements of the Wally120, but it can be scaled up to more needles easily. Here you can find all the documentation.</p><br/><p>The current design only includes a single Yarn carrier as the small size is not suited for complex patterns or multi tubes designs. So while you could use more than one it is not advised for this smaller version. The other limitation is that due to being smaller its maximum knit width is approximately 30 cm’s, this is still well suited for the smaller projects. However it is a cheaper and more practical alternative to the large machine to develop the overall system. As it simply clamps to any flat surface, is easy to move and store and easy to build.</p><br/><p>To finish this update I would like to share a short impression of the Wally 120 project. Here you can see the machine on action:</p><br/><p>Best,</p><p>Cees Jan and Gerard</p></div><br/><div><p>This post is not an update regarding the machine, it’s about something related to the project in a different way, maybe more important than the machine itself. It’s always great to have fun and learn while working on something you enjoy doing but it’s also important to do things for a reason once in a while, and that’s the combination of ingredients that created the OpenKnit project. To present OpenKnit I didn’t want to do just a technical video where a machine was shown, I wanted to go a bit further and talk about the implications of this technology in a more obvious way, so I created the Made In the Neighbourhood project to put some company names on the table, companies that perpetuate the status quo of the fashion industry and its model of production and consumption. I wanted to act at a local level and since I’m spanish I involved spanish clothing companies, companies international enough to scale the ideas globally, and of which two are based in my hometown, Barcelona.</p><p>After a month of the publication of the video project Vimeo sent me this email: note: ABASIC, S.L. = Desigual</p><p>This created a bittersweet feeling in me because all the comments on the video got lost and it left many broken links in all the sites it was posted in (thanks a million for that), but on the other hand, this tells me that I might not be doing things so wrong. I’m not sure why they did it, I guess because they saw something that they didn’t like, but this act reflects, from my point of view, on an attempt to hide something, maybe this new way of producing clothes? maybe some uncomfortable ideas that can be associated with their company?</p><br/><p>*UPDATE* April 9, 2014</p><div>I spent some days looking for a lawyer to write a proper counter-notification but they are too expensive for me, so I had to cancel the idea of answering back to the DMCA takedown, fortunately, Cory Doctorow helped me to get in contact with some Vimeo staff. They told me the video was target by a DMCA takedown notice for alleged copyright infringement so they had to take it down in accordance to their DMCA policies. They looked more closely at the merits of the DMCA and after further review, Vimeo determined that the DMCA was invalid because the allegedly infringing material (mannequins bearing the DESIGUAL logo) does not fall under the protections of copyright law so, a few days later, they were able to restore the original video :)</div></div><br/><br/><div><p>This collection was featured in the project being the first open-source clothing made with a machine. These four garments are a demonstration of the potential of OpenKnit, although, more sophisticated designs/clothes will be possible, hopefully, in a near future. Join the evolution.</p></div></div><div><p>Recent Posts</p><br/><br/><p>Categories</p><br/><br/><p>Meta</p></div></div></div> | + | |licence=CC BY-NC |