Pwdr

|

|

pwdr Basic Data Category: 3D printer URL (first publication): http://pwdr.github.io/ License: Project status:

Technical documentation Maturity of the project:

no no

Other

Assembly instructions are editable: Bill of materials is editable: Design files are in original format: No Free redistribution is allowed licence: No

Project management

Open-o-meter: 0 Product category: Electronics Contains original non-electronic hardware: Contains original electronic hardware: Contains original software: |

Inhaltsverzeichnis

Description

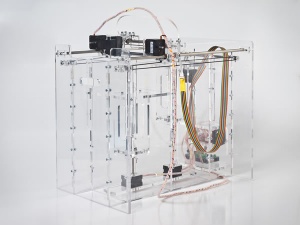

Pwdr Model 0.1

Pwdr is an open source powder-based rapid prototyping machine. Its goal is to promote experiments and innovations in powder-based rapid-prototyping. The machine is ready to use both the 3DP as the SLS process with minimal adaption, although the printer is currently prepped for 3DP.

Hardware

The Pwdr Model 0.1 consists of chassis, tool head and electronics. The printer entirely consists of off-the-shelf components. It has a simple design and can be built within a couple of hours. The machine is easy and affordable to build and modify. Building a Pwdr Model 0.1 machine costs about €1000,-.

Software

The accompanying software for the Pwdr Model 0.1 converts the CAD model in a printable format. This file is then uploaded to the Pwdr Model 0.1 micro-controller. The machine is controlled by easy-to-use software that allow full control of the printing process. The Pwdr Model 0.1 software has been based on open source tools like and .

Materials

A whole new range of materials become available for experimenting with open-source rapid-prototyping; for example, when using the 3DP process: gypsum, ceramics, concrete, sugar, etc. And when the SLS process is fully supported, plastic materials like ABS, PP, Nylon and metals become available as building material.A Hewlett Packard inkjet cartridge is used for the deposition of binder. The cartridge can be refilled with custom binders using a syringe. A custom binder of 20% alcohol and 80% water has been proven to work.

+ General Reviews

Public cad repository for non-electronic hardware

Public cad repository for electronic hardware

Public code repository

Assembly instructions

Bill of materials

Link github