Toolbox for Opto-Mechanical Components

|

|

Toolbox for Opto-Mechanical Components Basic Data Category: Business, industry URL (first publication): https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0169832 License: Project status:

Technical documentation Maturity of the project:

no no

Other

Assembly instructions are editable: Bill of materials is editable: Design files are in original format: No Free redistribution is allowed licence: No

Project management

Open-o-meter: 0 Product category: Business & Industrial Contains original non-electronic hardware: Contains original electronic hardware: Contains original software: |

Description

Nowadays is not uncommon to find headlines in the media where it is stated that 3D printing is a technology called to change our lives in the near future [1, 2]. For many authors, we are living the time of a third industrial revolution [3, 4]. However, we are currently in a stage of development where the use of 3D printing is advantageous over other manufacturing technologies only in rare scenarios. Fortunately, scientific research is one of them [5].

The implementation of opto-mechanical components using 3D printing technology is having a direct impact on the photonics community [6, 7]. Researchers are no longer constrained to work with commercially available products and therefore their experimental setups can be made more versatile. Thanks to the fact that the fabrication time is minimal, the characteristics and quality of the components can evolve very fast in the hands of researchers. Indeed this evolution process turns out to be a creative way to engage young researchers in photonics. Moreover, the new 3D printed components can be considered as prototypes, and thus other manufacturers can take these ideas to build better equipment or improve their own products.

A nice example to illustrate this is the Open-Source Optics Library [8]. A library of opto-mechanical components built from standard low-cost parts and 3D printed components aimed at providing a flexible and cost-effective alternative to current commercial alternatives. The library is composed of a broad selection of optical components ubiquitous in any optics experiment such as a lens holder [9], a screen/filter holder [10, 11], a lab jack [12], a fiber optic holder [13], a kinematic mirror/lens mount [14], a parametric open-source chopper wheel [15], among others. To arrange the components in a particular configuration, the standard optical table is exchanged by a 8mm smooth rod from which each element is fixed [16–19] or by a set of magnetic bases [20] that can be fixed to any already available steel plate. Since each component 3D printed is a parametric design in OpenSCAD [21], it can be easily modified, improved or customized by changing a few lines of code.

Interestingly, more advanced equipment is also accessible by combining 3D printed components with an Arduino or a Raspberry pi card that provides sensing, processing and actuation capabilities. This is the case of the open-source colorimeter [22] used for determining the concentration of dissolved species, the DIYbio centrifuge [23] used for DNA extraction, the open-source syringe pump [24] developed to provide a carefully controlled dose of a given reagent, the open-source quartz crystal microbalance [25] capable of measuring phenomena at molecular scale in fluids, vacuum or air, or the Smartphone laser beam spatial profiler [26] that can be used to characterize easily the spatial profile of a laser beam, just to name a few. In all these cases, the gap of overly engineered components for experimental setups is filled with an equipment that despite costing a fraction of its commercial counterpart can be used to perform state-of-the-art research.

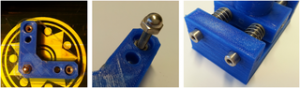

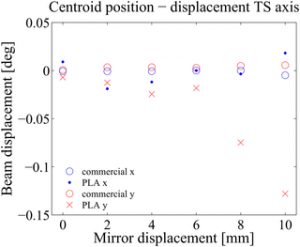

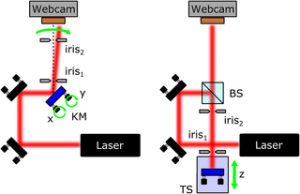

In this paper we report the design and construction of a set of opto-mechanical components intended to complement the library of open-source optical components already available on the web [8, 27, 28]. In our approach, we put special emphasis on evaluating the performance of each component by carrying out a quantitative comparison with respect to its commercial counterpart. The components are developed with 3D printers based on FFF [29] that can be used in various experimental setups in photonics, either for research or teaching. In particular, we report results for a kinematic mount, a translation stage, and an integrating sphere.

Since 3D printers based on FFF are becoming more affordable, the opto-mechanical components of our set can be fabricated practically in any location. It is important to highlight that since the components fabricated have a similar performance than low-end commercial alternatives in terms of stability and robustness, the approach presented here makes photonics more accessible to industry and academia in regions and countries with scarce resources, enlarging significantly the size of the community interested in performing experiments in photonics and related fields [30]. The ideas presented here also constitutes a new path to reduce increasingly rising costs, and in certain places can constitute a way to overcome funding restrictions and large lead times due to customs and administrative procedures [6].

+ General Reviews

Public cad repository for non-electronic hardware

Bill of materials