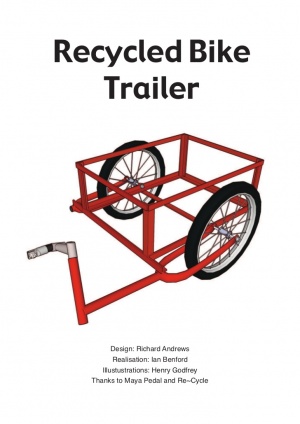

Trailer fabrication

|

|

Trailer fabrication Basic Data Category: Projects URL (first publication): https://de.slideshare.net/cbcad2010/trailer-fabrication

no no

Other

Design files are in original format: No Free redistribution is allowed licence: No

|

Description

SlideShare verwendet Cookies, um die Funktionalität und Leistungsfähigkeit der Webseite zu verbessern und Ihnen relevante Werbung bereitzustellen. Wenn Sie diese Webseite weiter besuchen, erklären Sie sich mit der Verwendung von Cookies auf dieser Seite einverstanden. Lesen Sie bitte unsere und die .

SlideShare verwendet Cookies, um die Funktionalität und Leistungsfähigkeit der Webseite zu verbessern und Ihnen relevante Werbung bereitzustellen. Wenn Sie diese Webseite weiter besuchen, erklären Sie sich mit der Verwendung von Cookies auf dieser Seite einverstanden. Lesen Sie bitte unsere unsere und die .

- Teilen

- Gefällt mir

- Herunterladen

Veröffentlicht am 20. März 2012

Gehören Sie zu den Ersten, denen das gefällt

Trailer fabrication

Sie haben diese Folie bereits ins Clipboard „“ geclippt.

Sie haben Ihre erste Folie geclippt

Durch Clippen können Sie wichtige Folien sammeln, die Sie später noch einmal ansehen möchten. Passen Sie den Namen des Clipboards an, um Ihre Clips zu speichern.

+ General Reviews